neos aware features

Neos Aware recommends modeling, simulation and mathematical optimization as an alternative to a trial - error procedure.

PROJECT MODULE

To be competitive and at the vanguard of your market, your business needs must be verified to meet the current customers’ needs and also if requires to anticipate future requirements.

Cost reduction, environmental initiatives, scarcity of raw materials, rising transportation costs, large format, reduction energy consumption, etc., that are requirements are driving companies to constant product development.

In order to be in continuous development, Neos-Aware has a project module where, from a set of raw materials and restrictions, you get a new ceramic composition is compliant with the established objectives.

Architecture

The configuration of a project is accomplished in four steps:

Selection of raw materials

Definition of ceramic processing

Defining physicochemical properties to be considered

Choice of equipment and units’ specific to be used for the project

Formulation

The workflow starts with the proposal of the compositions to be tested, Neos-Aware has a formula analysis algorithm with the aim of achieving maximum information with the minimum number of compositions, however performing these compositions can be carried out according to the technician or using the software learning process. The technician can modify or propose new compositions from his own technical experience or from the software awareness.

The results obtained for each composition are introduced in the part of the project dominated workbench tables, which can be customized for each client according to their needs. It also has a tool that minimizes the number of tests for each composition, by applying a powerful predicting algorithm.

RAW MATERIAL MANAGEMENT MODULE

The database of raw materials is essential for the characterization and use in the calculations for each project.

This module contains:

- Management of new raw materials

- Module characterization of new materials

- Simulation and optimization module

- Definition of control conditions of each raw material

- Module of management & quality control of new lots

The proposals management of new suppliers and raw materials allow, after their characterization to validate its use in projects, taking into consideration the costs and benefits as well as the identification of an acceptable price in each case.

Neos-Aware can manage the quality of raw materials, including inspection during reception of a new batch, thus ensuring quality stability.

AUTHORIZATION MODULE

The platform has different levels of authorizations according to user roles, ensuring data integrity and know-how of the company.

All experimental knowledge becomes information for the company, regardless of the rotation of the personnel performing these functions, in order to ensure the integrated management within the company.

Neos-Aware reduces the risk of unauthorized changes, prevents data loss and facilitates the traceability of result

LABORATORY MANAGEMENT MODULE

Standardization of laboratory processes

Treating experiments data efficiently and controlled, is essential to obtain an accurate result.

Neos-Aware has a lab management module including:

- Analytical Procedure

- Management of laboratory equipment

- Work units

- Calibration management

- Document Management

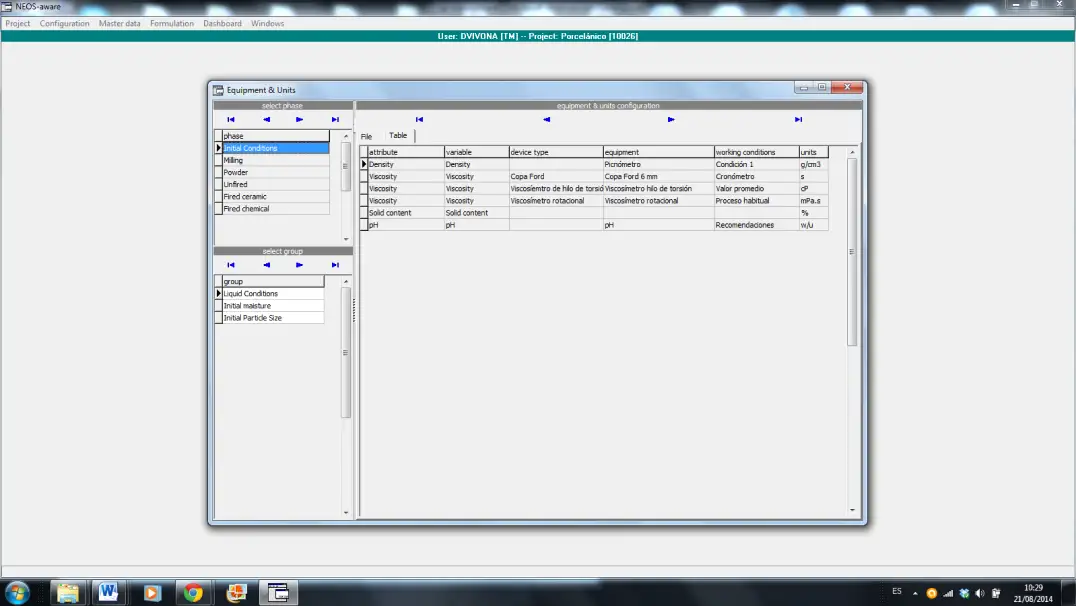

Example of Management of Equipment and Units:

Methodology of tests well described and documented:

CUSTOMER TRACKING MODULE

Neos Aware provides customer tracking.

OPTIMIZATION MODULE

Optimization with Neos-Aware offers extensive information, which allows growth of knowledge for both, the user and the platform.

| Example | ||

|---|---|---|

| Target | Attribute/Raw Material | Cost Minimization |

| Restriction | Absolute Attribute | MOR dry > 30 Kg/cm2 |

| Attribute versus another | Sintering temperature | |

| Relationship between attributes | (∆ srinkage)/(∆ Temperature)<0.05 | |

| Colour parameter | ∆E<0.2 | |

| Percentage Raw material | % Clay 1 < 50% | |

| Relationship between attributes | Clay 1+ Clay 2 > 20% | |

| Percentage of contaminants | F- < 600mg/Kg | |

| Percentage between oxides | (% SiO2)/(% Al2O3)>3 | |

(IMAGEN)

SIMULATION MODULE

Neos-Aware has a simulation module for body compositions.

The learning platform process for the analysis of results allows the technician to predict the final properties of the body composition from a proposed formula. The virtuous circle is established between prediction and auto-learning, coming from experimentation, and facilitates an improvement of the calculation’s accuracy.

With a small amount of testing, the system achieves the prediction at 2sigma (95.5% probability), providing high reliability using the simulation tool for body compositions.

The technician can check all the ceramic properties before performing laboratory tests, reducing research time and focusing tests to obtain the desired result.

(IMAGEN)

PERFROMANCE EVALUATION MODULE

Neos Aware Workbench enables a technician to introduce and manage the ceramic tests, and also delivers key features for performing difficult change management and documentation tasks that normally require much time and effort.

(IMAGEN)

Analysis of Results

In the classical version, multivariate analysis of results is one of the most difficult stages because the linked results in different compositions bind with multiple properties evaluated.

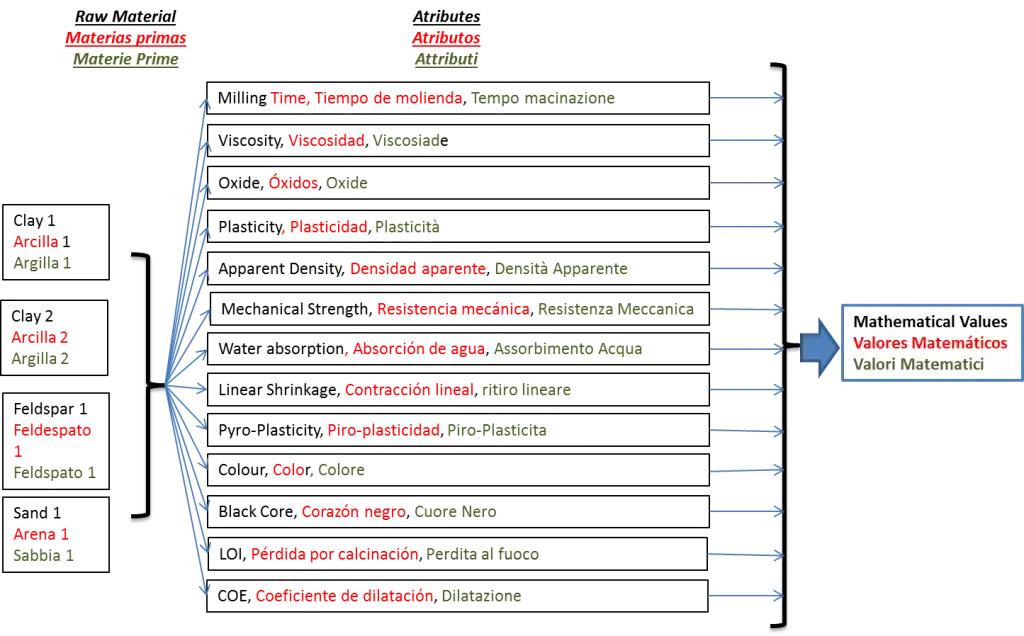

(IMAGEN)

Neos-Aware translates this set of results into mathematical values, which are then fed into the mechanism of artificial intelligence, from which moment the process of self-learning platform is unlocked and started.

(IMAGEN)

In addition, experimental results are verified on a control chart. This action allows an assessment of the errors and the accuracy of the calculations of a simple and visual way.

(IMAGEN)

ENERGY MODULE

Neos-Aware has a powerful module that allows evaluating the energy consumption of a composition against a proposed industry standard composition.

This assessment is performed at different production process stages;

Grinding: Rating milling times, in order to increase productivity with the same energy cost or reduce of grinding time with a consequent savings of electricity consumption.

Spray drier: From real knowledge of the energy consumption of industrial spray driers, was modeled estimated consumption for given composition against a standard reference. Thus, you can know the impact of the solid content increase, with the consumption of deflocculant and energy required for drying.

Firing: The modeling has been performed in many industrial kilns, in order to simulate the processes established in the kiln during the firing process (interactions between different modules of the kiln, between the side, top and bottom walls, roller screen effect, atmosphere and composition, chemical reactions during firing, etc.). In this simulation, considering all variables that affect the gas consumption as a result of the formulation (sintering temperature, hold time, bulk density, type of support, percentage of occupied kiln carpet, thickness of the pieces, etc.). Finally, you get a percentage of energy consumption for the new composition, expressed against the standard composition introduced.

With the global trend of insufficiency and rising energy costs, and environmental awareness, the use of this module, enables design compositions with greater reductions of energy consumption and emissions of greenhouse gases to avoid global warming.

For the realization of this module Neos has had collaboration with the ITC (Institute of Ceramic Technology).

BAND MODULE

Neos Aware Workbench enables a technician to perform and run ceramic tests.